Customized mold

Self-developed infrared sensor design software to ensure that customer needs are met. All customer development products (design verification, mold processing, testing, production, inspection, packaging) are all completed within the company to fully guarantee product delivery. The molds used for all products are assembled from the original molds, retaining the original real design, reducing the loss of precision and wasted time caused by the second mold turning. Generally, formal samples can be provided within 30 days for new products.

keyword

Custom made mold

Category

Product Details

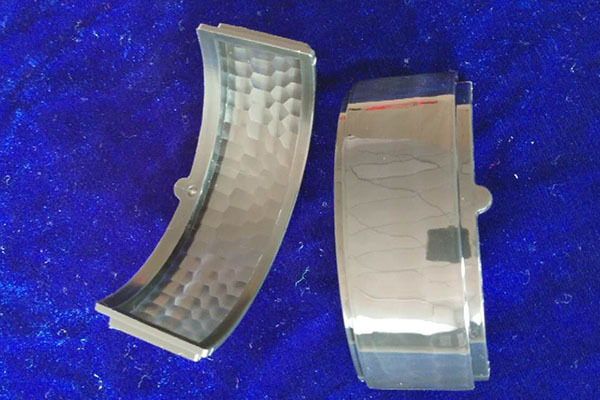

1. Mold processing capacity:

Tooth tip R0.01MM, ring distance less than 0.03MM

The maximum processable mold diameter is 2000mm

The smallest machinable mold diameter is less than 1mm

The longest focal length can be designed and processed over 5 meters

The minimum focal length can be designed and processed below 5MM

The highest finish R0.014 microns, generally R0.02 microns

2. Infrared lens customized demand information:

(1) Probe Model Specifications Product Drawings

(2) 3D or 2D diagram of probe placement relative to lens

(3) Required sensing angle and sensing distance (horizontal direction and vertical direction)

(4) Indoor application OR outdoor application

(5) Color requirements

(6) Is there any anti-pet function?

3. Mold making

Self-developed infrared sensor design software to ensure that customer needs are met. All customer development products (design verification, mold processing, testing, production, inspection, packaging) are all completed within the company to fully guarantee product delivery. The molds used for all products are assembled from the original molds, retaining the original real design, reducing the loss of precision and wasted time caused by the second mold turning. Generally, formal samples can be provided within 30 days for new products.

4. sign a contract to agree on the specific product testing time.

Related Products