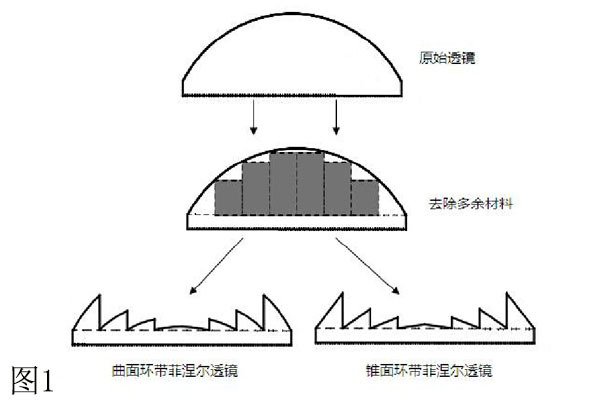

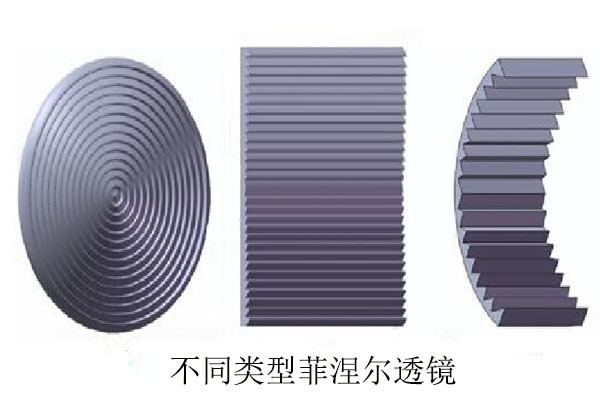

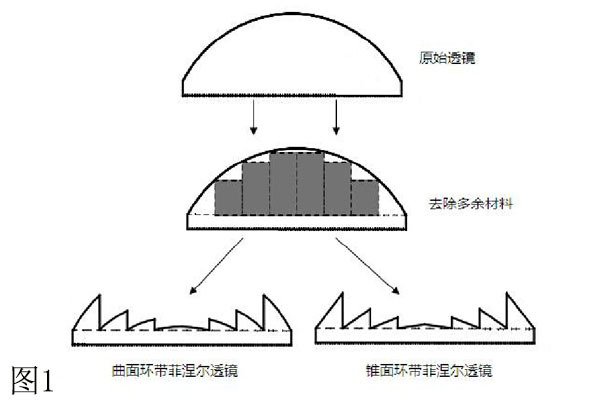

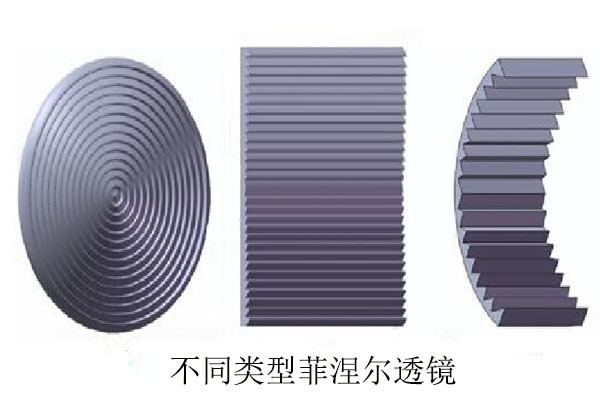

The design principle of Fresnel lens is that the lens is no longer treated as a whole during processing, but as an entity composed of many microstructures that retain the radius of curvature of the original convex lens and remove the intermediate pair of rays. A part of the deflection that does not work or has little effect. The design process of the Fresnel lens is shown in Figure 1. Figure 2 is a physical diagram of a planar Fresnel lens.

In the early days, due to material limitations, the lenses were made of glass. Fresnel lenses were no exception. However, if the Fresnel lens was processed by conventional grinding and polishing, it took a long time and was labor intensive, which made the cost. Too high. Later, people invented the processing method of hot pressing of metal molds, but the surface stress of the glass was too large, which caused some details to be suppressed during hot pressing, which made the Fresnel lens not achieve the expected use effect. Fresnel lenses cannot be promoted. Since 1950, a new material, polymethyl methacrylate (PMMA), has been widely used because of its optical properties, which are very similar to glass, and its light weight. The lens is made. In 1951, Miller et al. succeeded in producing Fresnel lenses using PMMA. Since PMMA was low in cost and stable in nature, people began to use Fresnel lenses instead of glass.

With the advancement of technology, the lens processing technology continues to advance, the optical performance of Fresnel lens is getting better and better, and it is gradually being valued in many fields. Fresnel lens has thin thickness, small quality, low cost and good light collecting effect. The advantages of many other fields have begun to pay attention to the application of Fresnel lens. The solar concentrating photovoltaic industry has put the Fresnel lens into use. With the development of technology, the scientific and technical personnel are still carrying out the concentrating performance of the Fresnel lens. Further research and experiments have yielded many gratifying results.

Since 1970, the National Aeronautics and Space Administration of the United States has begun a detailed study of Fresnel lenses, and many of the research results have played a role in marking the future of scientists on the road of Fresnel lens research. In 1979, Kritchman developed a high-focus concentrating curved line to focus Fresnel lens. The biggest advantage of this lens is that it has a qualitative leap in concentrating performance. In 2006, Korean Kwang sun Ryu proposed a method for dividing the surface of a Fresnel lens into small modules. The method uses software to process the small modules of the Fresnel lens so that the incident sunlight can be uniformly irradiated on the silicon photocell. In the past, the problem of the solar light being easily concentrated in a small place and burning the battery was solved.

Later, American Daniel conducted an in-depth analysis of Kwang sun Ryu's Fresnel lens to design a multi-point focusing Fresnel lens with higher illumination uniformity than before. The lens optimizes the thread of a conventional Fresnel lens, changing the original single-point focus mode to multi-point focusing, so that the focus spot of the Fresnel lens is no longer confined to a certain position, and the illumination uniformity is thus improve.

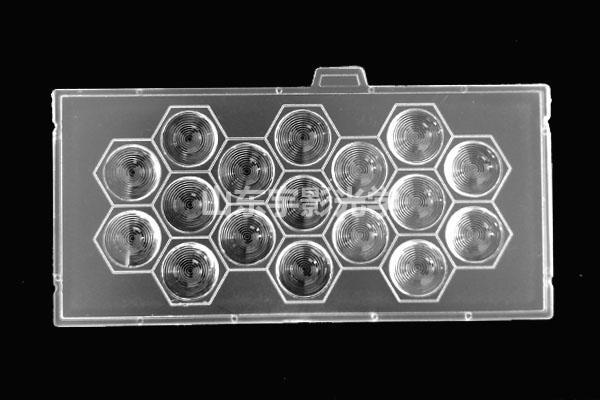

In China, Shandong Yuying Company's predecessor, Linyi Luobei Optical Instrument Factory, was engaged in the production and research and development of Fresnel lens in the late 1960s. It was restructured into a private enterprise in 1992 and later renamed Shandong Yuying Optical Instrument Co., Ltd.

In the early 1990s, Guo Xiaowu of the Institute of Physics of Shaanxi Province proposed a unified design method for comprehensive Fresnel lenses, which played a guiding role for later scholars to study Fresnel lenses.

In 2002, Jia Fuyun found that when the Fresnel lens is focused on the cylindrical line, the F number is around 1.3, and the optical efficiency can reach more than 85% when the concentration ratio is 5 or 6.

In 2007, Li Weiqian designed a Fresnel lens that abandons the traditional concentric annular structure and uses Archimedes spiral grooves. This lens has no essential difference in application from concentric circular Fresnel lenses. But for the Fresnel lens created a new form of structure.

In 2009, Yao Xuhong discovered that the concentrating efficiency of Fresnel lens is proportional to the intensity of incident light. At the same time, due to the existence of certain light reflection on the surface of Fresnel lens, the transmittance is inversely proportional to the angle of incident light.

In 2011, Zhao Huifu studied the performance of Fresnel lens indoors and outdoors. The results show that the light transmittance is unchanged in indoor and outdoor test errors, but the test error of concentrating efficiency is lower than that of outdoor test. The reason for this difference is to provide reference for the testing of Fresnel lenses in the future.